WPS/PQR

ASME/CSA/AWS/ISO Welding Procedure Qualification & Development

Quality Control Manual

Development of comprehensive QC manuals aligned with CSA, ASME, AWS, and Technical Safety BC standards to ensure compliance and project success.

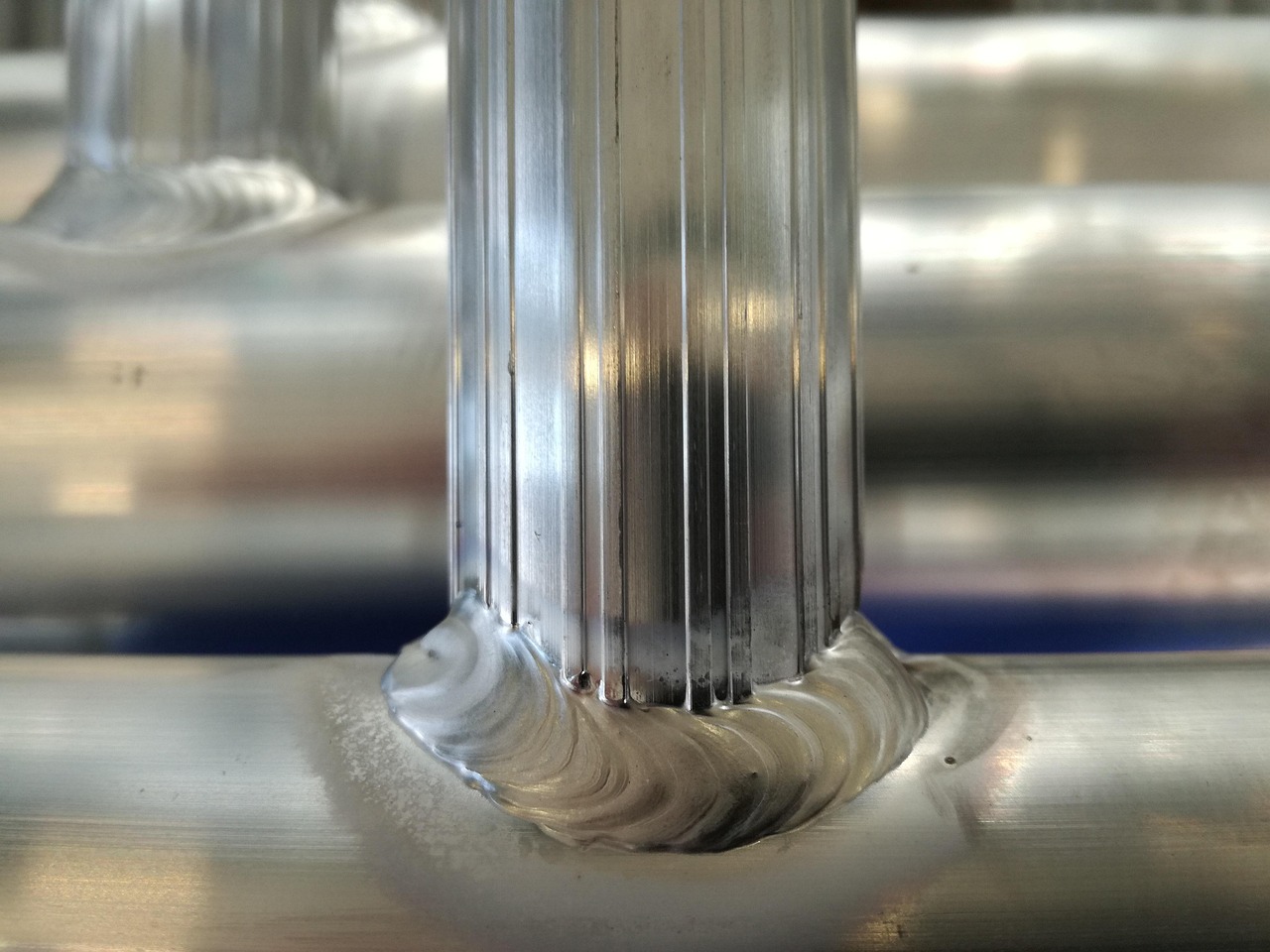

Welding Visual & NDT Inspection

Certified inspections to ensure weld quality, compliance, and safety from start to finish.

Most Popular Services

Quality Control Manual Development

Comprehensive manuals aligned with CSA, ASME, AWS, and Technical Safety BC standards.

Welding Procedure & Welder Qualification

WPS/PQR development and welder qualification for all codes and project requirements.

Welding Visual Inspection

Certified inspections to ensure weld quality, compliance, and adherence to standards.

Non-Destructive Testing (NDT – MT & PT)

Magnetic Particle Testing (MT) and Penetrant Testing (PT) to detect surface discontinuities and ensure structural integrity.

Project Quality Support & Oversight

From material sourcing to in-process verification and final sign-off by inspectors and regulatory authorities.

Contractor Licensing & Compliance Assistance

Support for contract tray licensing, regulatory approvals, and procedural compliance.

Technical Consulting & Problem Solving

Expert advice on welding, codes, standards, and complex project challenges.

Use this paragraph to describe what you do. This is a great place to let your visitors know who you are.

CWB Retained Engineering Services

Across British Columbia and Canada, CWB (Canadian Welding Bureau) certification is a legal requirement for companies involved in fabricating and erecting welded steel and aluminum structures. This includes everything from tank supports and welded-on ladders to portable structures such as skid packages.

To be certified under the CSA W47.1 (steel) or CSA W47.2 (aluminum) standards, a company must either:

Employ a CWB-certified welding engineer (Division I), or

Retain a CWB-certified welding engineer (Division II)

For welded steel and aluminum structures, compliance with CSA W59.1 (structural steel) and CSA W59.2 (structural aluminum) is also mandatory to ensure quality and safety.

If your operations fall under Division II, Glent Works Canada Inc. is your trusted partner for meeting these regulatory requirements efficiently and cost-effectively. We provide expertise in:

CWB welding procedure development and registration

Visual welding inspection and NDT (MT, PT)

QA/QC program setup and compliance monitoring

Glent Works ensures your fabrication processes comply with Canadian welding codes while helping you optimize costs and maintain high-quality standards.

Glent Works Canada Inc. offers Retained CWB Welding Engineer services to support your structural steel and aluminum fabrication and erection activities. Our team of CWB-certified engineers acts as your on-demand engineering department, providing the expertise and certification support you need—without the cost of a full-time hire.

Our Retained Welding Engineering Services Include:

Due diligence review and guidance to meet CWB application requirements

Assistance with CWB applications and certification processes

Development of Welding Procedure Specifications (WPS) and Welding Procedure Data Sheets (WPDS) for steel and aluminum

Acting as your official Retained Engineer

Quarterly site visits and audit reports as required by CSA W47.1/W47.2

Ongoing compliance support, including interpretation of CSA W47.1, W47.2, W59.1, and W59.2 standards

Glent Works ensures your welding operations remain compliant, efficient, and fully supported by certified engineering expertise.

Why Choose Glent Works for Retained Welding Engineering

For companies where steel and aluminum fabrication and erection are a minor part of your overall services—such as Heavy Industry Contractors or Fabricators—employing a full-time CWB Certified Welding Engineer may not be cost-effective. Glent Works’ Retained Engineering Services provide the expertise you need on-demand, helping you maintain full legal compliance under Division II without the expense of a permanent hire.

Our team of CWB-certified Professional Engineers (P.Eng.), registered in British Columbia, Alberta brings decades of experience and technical leadership. We support clients across BC, Alberta and internationally, ensuring your welding operations remain compliant, efficient, and fully backed by certified engineering expertise—wherever your projects take you.

Quality Assurance & Quality Control (QA/QC) Programs for TSBC

Glent Works Canada Inc. specializes in developing Quality Control Program (QCP) manuals to support contractors in obtaining and maintaining licences under the Boilers, Pressure Vessels, and Refrigeration (BPVR) Regulations in British Columbia. Our expertise helps clients comply with TSBC requirements for licence classes A, Au, Ap, B, PW, REF, SRV, and MA.

Class B & REF Licence Requirements (Effective January 1, 2026):

Submission of a QCP manual is mandatory for new applications and renewals.

The manual provides a detailed overview of processes, procedures, and forms used in regulated pressure equipment work.

Licensed contractors, typically in the role of Quality Control Manager, are responsible for approval, updates, and implementation of their QCP manual.

Transitional Support for Renewals:

Existing clients may renew their licence first and submit their QCP manual before the next renewal date in 2027.

Glent Works can assist in documenting, reviewing, and preparing your manual for TSBC acceptance.

Support for New Licences:

Submission of a QCP manual is required at the time of application.

Our team ensures your manual meets TSBC requirements efficiently and accurately.

Contact Glent Works today to ensure your QA/QC systems comply with TSBC regulations and support your contractor licensing needs.

TSBC QA/QC Manual Reviews & Consulting

Equipment Certification & Inspection Services

At Glent Works Canada Inc., safety, reliability, and compliance are non-negotiable for heavy industrial equipment. We provide expert inspection and certification services in line with Engineers and Geoscientists British Columbia (EGBC) requirements, WorkSafe BC, and the latest regulatory standards—ensuring your operations run safely, efficiently, and cost-effectively.

Why Choose Glent Works:

All-in-One Service: Our team includes in-house Level 1, Level 2, and Level 3 certified inspectors, CGSB-approved MT/PT technicians, and EGBC-registered Professional Engineers, allowing you to consolidate services under a single work order and reduce costs.

Regulatory Compliance: All inspections are conducted in accordance with the Professional Practice Guidelines – Annual Equipment Inspection and Certification in British Columbia, EGBC requirements, OHSR, and applicable codes (ASME, CSA W59, CWB).

Certified & Experienced Team: Our inspectors are certified under CSA W178.1/W178.2, supported by EGBC-registered engineers who understand the professional and ethical obligations under the Engineers and Geoscientists Act, ensuring public safety, proper documentation, and regulatory compliance.

Our Expertise Covers a Wide Range of Equipment:

Overhead, gantry, and mobile cranes

Hoists, manlifts, chainfalls, and aerial lifts

Forklifts, picker trucks, and mobile equipment

Earthmoving, drilling, and mining machinery

Service rigs, knuckle and articulating booms, telescoping frames

Materials handling equipment and other critical machinery components

- Self-propelled boom-supported elevating work platforms

EGBC Guidance & Professional Practice:

Our inspections follow EGBC professional practice guidelines, which define the standard of practice for engineers performing equipment inspection and certification. This includes:

Roles and responsibilities of all stakeholders (Owner, Operator, Engineer of Record, inspectors, and authorities)

Required skill sets and competencies for inspection personnel

Proper use of Certification forms, signed and sealed by the Engineer of Record (EOR), providing a formal record to clients and regulatory authorities

Glent Works Canada Inc. ensures your equipment is certified, compliant, and safe, giving you confidence in operations while meeting EGBC and WorkSafe BC requirements.

Owner/Inspector Services for Pressure Piping Projects

At Glent Works Canada Inc., we provide professional Owner/Inspector services for pressure piping systems in full compliance with ASME B31.1, B31.3,31.5,31.9 and B31.12 standards. These services are mandatory for all regulated piping projects to ensure safety, quality, and regulatory compliance.

Why an Owner/Inspector is Mandatory

For regulated piping projects, having a qualified Owner/Inspector is essential to:

Ensure compliance with ASME piping codes

Oversee installation, fabrication, and repair activities

Validate welds, materials, and testing procedures

Protect the integrity and safety of your pressure systems

Our Expertise

Our services are led by a Certified Pressure Equipment Inspector (PEI) from the National Board of Boiler and Pressure Vessel Inspectors, USA, experienced in:

New Construction: Inspection during fabrication and installation

Repair: Oversight of repairs and modifications to pressure systems

In-Service: Periodic inspection and testing of existing piping systems

We provide inspection and oversight for:

Pressure piping installations and modifications

Hydrostatic and pneumatic testing

Welding inspection and procedure verification

Documentation and compliance reporting

Benefits of Using Glent Works

Certified Expertise: NBBI Certified PEI for new, repair, and in-service inspections

Regulatory Compliance: Full adherence to ASME B31 codes and local safety regulations

Risk Mitigation: Reduce project risks and costly rework by early detection of issues

Complete Documentation: Detailed reports for clients and regulatory authorities

How We Work

Review project specifications, procedures, and drawings

Conduct inspections during new construction, repairs, and in-service evaluations

Verify compliance with ASME codes and owner requirements

Provide certified reports with recommendations

Glent Works Canada Inc. provides Owner/Inspector services across BC, Alberta, and internationally, giving you full confidence that your pressure piping projects meet mandatory safety and quality standards.

Contact us today to engage a certified PEI for your project.